Cucumber handling system

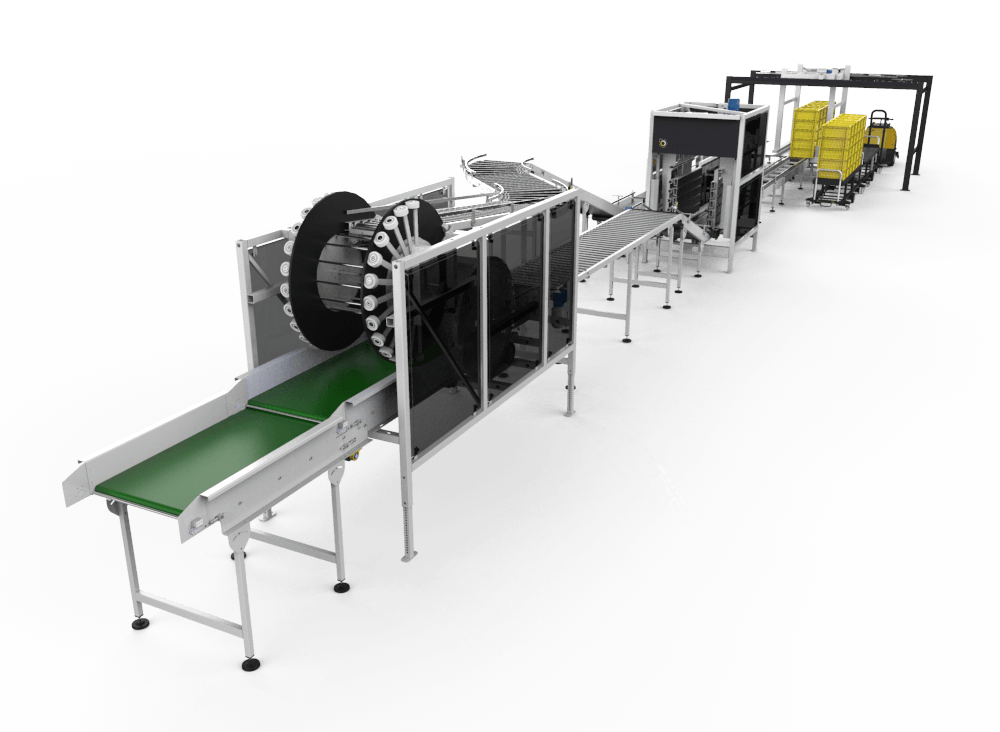

The cucumber handling system is a system that is used to automate the handling process of the cucumber from the harvest box up to the weighing unit.

There are different degrees of automation: The automation can start in the greenhouse, or it can start in the packing hall.

- Fully automated: the harvesting carts are automatically driven to and from the cucucmber handling system, guided by an induction course. A Power Bee AGV is used to pull Bo Cart harvesting carts with rollertrack.

- Semi-automated: You can also use a cucumber handling unit in combination with a hand-operated Power Bee which pulls Bo Cart harvesting carts with rollertrack.

A handling system is modular, always custom made: depending on the needs/desires of the customer and the available space in the packing hall. Together with the customer, Bogaerts greenhouse logistics always finds the best solution.

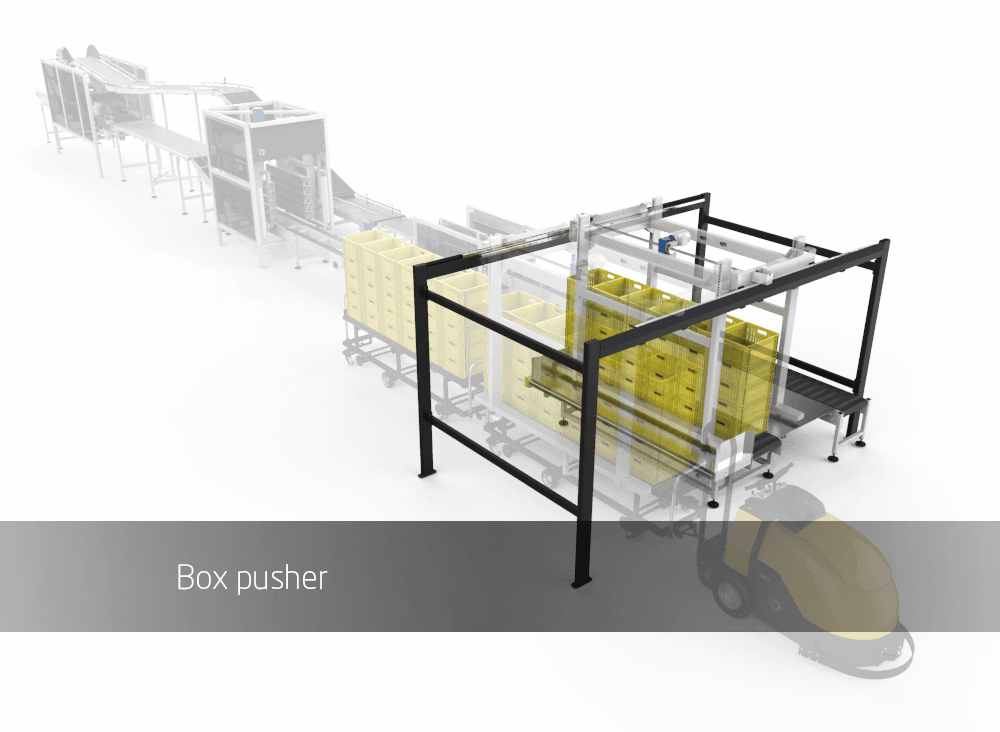

Box/crate pusher

The Power Bee automatically drives the Bo Carts into the pusher unit. The boxes are then pushed off the Bo Cart onto a conveyor belt.

Modular belt conveyors

With different lengths.

Destacking unit

The conveyor belt transports the boxes through the destacking unit, which unstacks the boxes from 6-7 boxes high to 1 box high.

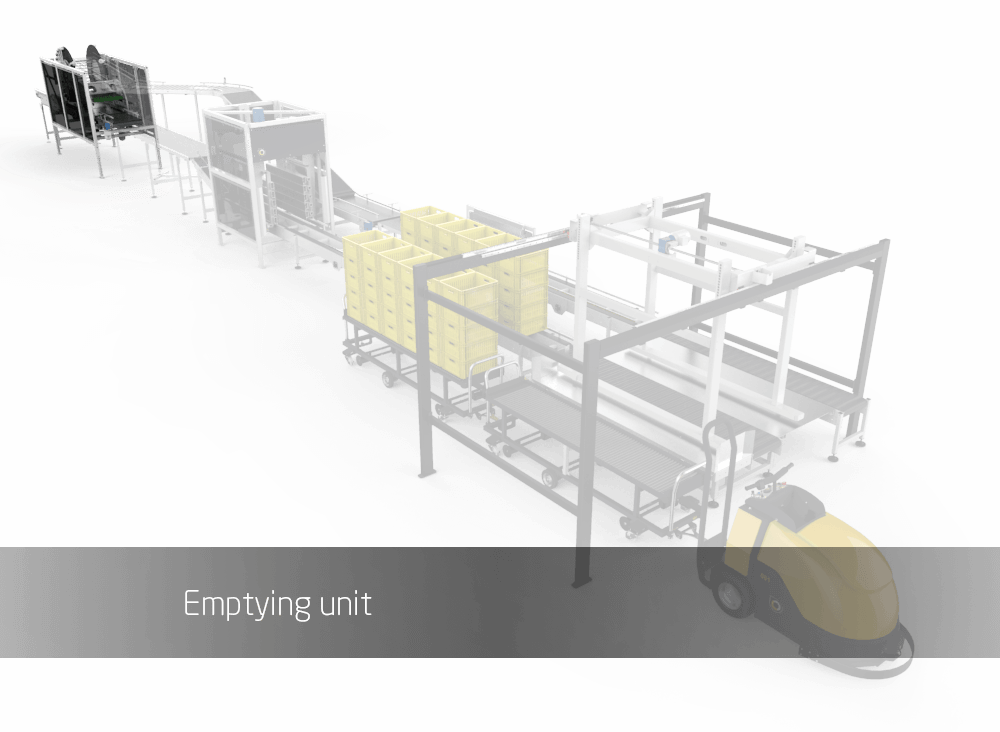

Emptying unit

The unstacked boxes go to the emptying unit. The unit flips over the boxes very carefully so the cucumbers do not get bruised. The cucumbers go to a weighing unit.

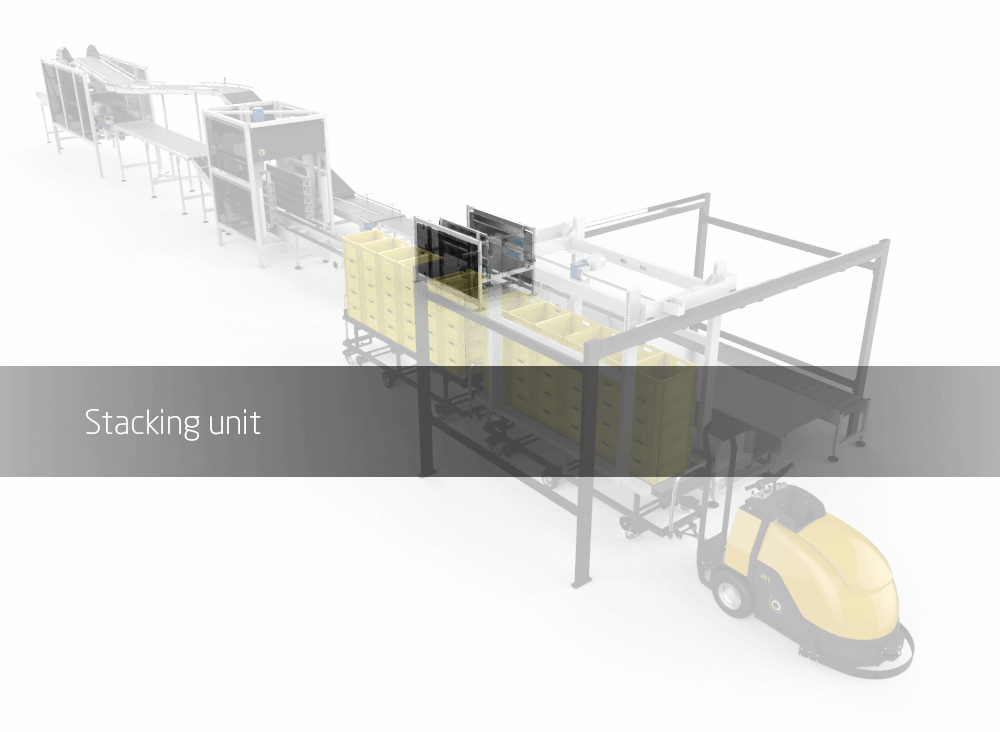

Stacking unit

The empty boxes are stacked by the stacking unit and transported to the pusher unit, where they are pushed back onto the Bo Carts.

© BogaertsGL.com | Privacy policy